Story from Behind-the-scenes

At first glance, the designs from our knit series appear simple. Truthfully, it's been a continuous process of invention to bring these industry-first products to life. Here, we pull back the curtain and share the story behind the development.

Uncompromising Standards

In 2016, our designers had an idea for knit items that would fit newborn babies' tiny feet. Every factory turned them down. They all said the high degree of difficulty would make it impossible to produce at scale.

Every factory except for a local manufacturer in rural Niigata Prefecture named Yoshihide Co.

Specializing in knit products, they took on the challenge. They wanted to make unique products and this was definitely one of them. It meant developing and implementing a new manufacturing method from scratch. Hard work and trial and error eventually resulted in our signature knit pants.

One Garment from One Thread

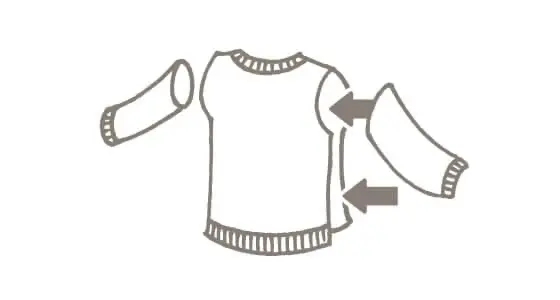

Knit clothing is usually made piece by piece and assembled together at the end. This means it will feel as tight or as loose as the seams allow. For babies and their sensitive skin, these seams are also itchy and rough.

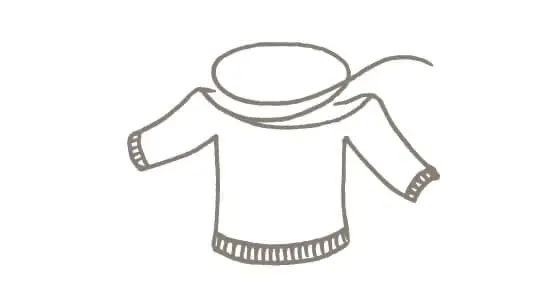

Together with MARLMARL's designers, Yoshihide's team brought the "Wholegarmet" method to life. This technology knits the whole garment all at once rather than piece by piece.

It makes the knitwear seamless and extra stretchy. The soft finish provides maximum comfort and fit. Since every stitch is stretchable, it is perfect for babies who want to move freely.

Continuous Improvement (and more Trial & Error)

Since then, our knit product line has expanded over the years. But for the 2023 Autumn/Winter season, our designer wanted to push the boundaries even further. She wanted to knit the traditional Japanese "yamaji" pattern.

Not only was this a first attempt, but knitting patterns with the Wholegarmet method was unheard-of in the industry.

It was another product that needed to be developed from scratch. Yoshihide's president took this challenge head-on. "I don't want to make anything that's the same as another company's. I don't want to make something that will be copied. I don't want to make something that will be imitated by other companies."

Thoughts on Making Baby Gifts

Let's close this out with more from Yoshihide's president:

The WHOLEGARMENT process produces a single piece of knitwear from a single thread. This production method minimizes waste because almost no scraps are leftover or cut-off.

In particular, the loss rate for MARLMARL products is less than 1%. Even the yarn used for knitting out the fabric, called discarded knitting, is kept for cleaning the factory.

Because MARLMARL makes gifts for children, they also consider the future of manufacturing in their production plants. This was another product we developed from scratch. Another challenge we had never attempted before. In the end, we were able to expand and create new possibilities for the factory!